If you are a manufacturer, then you should be familiar with the processes about

- Products

- Customers

- Suppliers

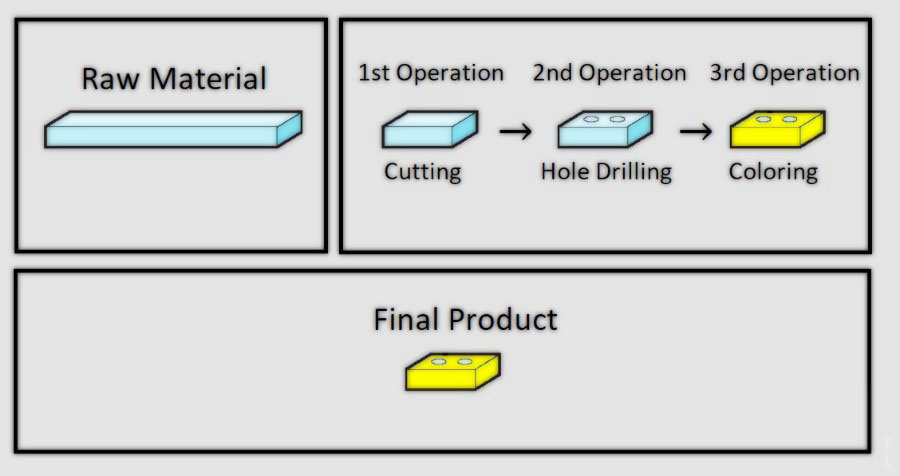

This three resources are the main source of your manufacturing process. To start with product; when you have a product to produce, then you should have value added operations. Prodrun lets you to track all your products and its value added operations in real-time from raw material to the final product.

You can organize bill of materials, your detailed product information, operation set-up and process time and semi-finished product.

Items on your production plant can be any form like,

- Raw Material

- Work-in-Progress Inventory

- Semi-finished Goods

- Maintenance, Repair and Operating Supplies

- Final products

With Prodrun, you can track and analyse all of them within seconds.

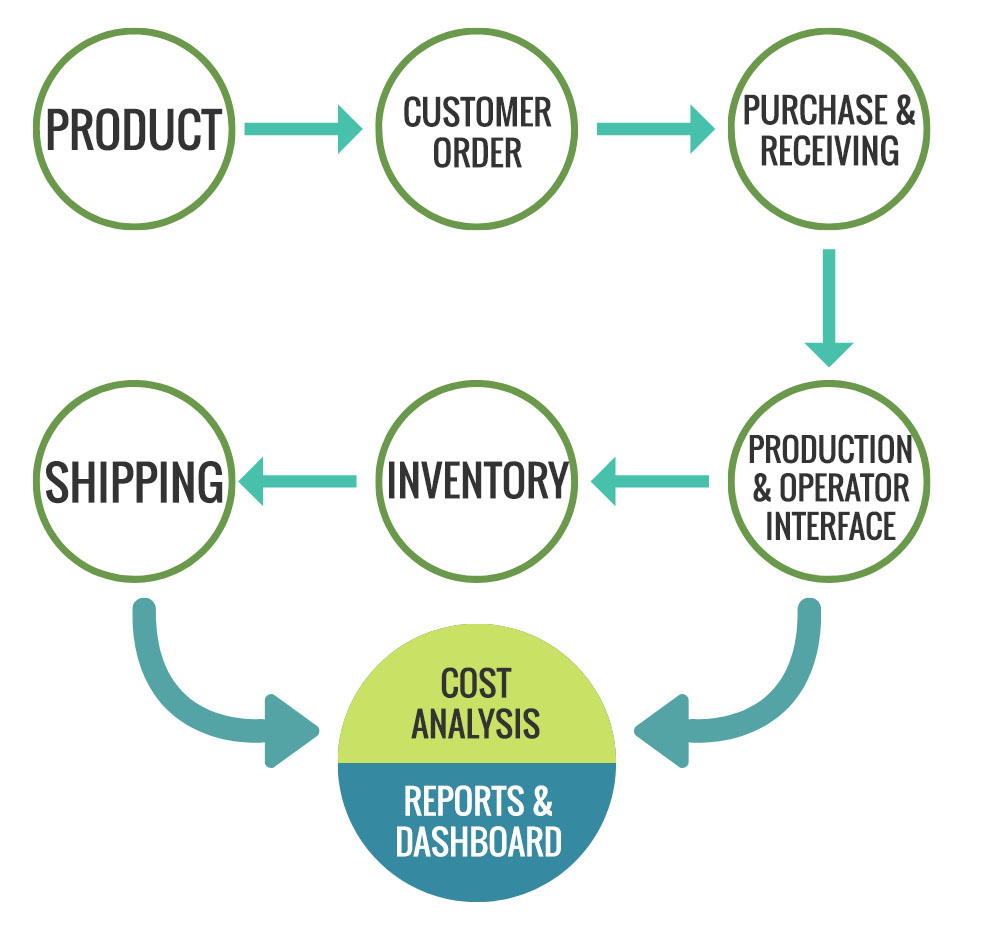

Prodrun’s business processes designed with the traceability principle can be seen in the graph below.