Purchase item that required for the production should be any of these:

- Raw material

- Tooling

- Manufacturing support item

- Mold

- Supplies

- Packaging material

- Services (required for specific work order)

- Other

All of them are related to your specific value added operations. To integrate a purchase order into a traceability system, you should define your purchase items and suppliers.

There are some important data that need to be tracked in raw material receiving process.

- Order date

- Delivery date

- Status

- Quantity

- Price

- Currency type

- Related work order

- Related customer order

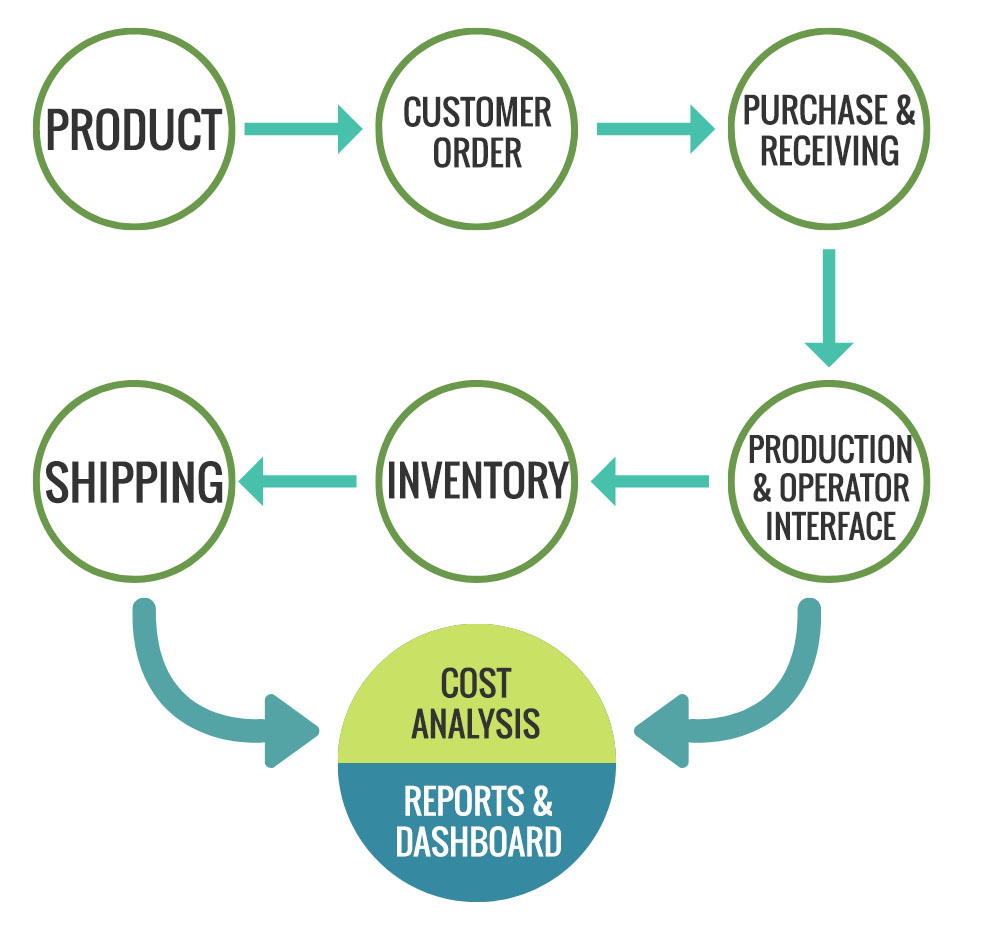

Prodrun’s Purchase Management module traces the purchasing process starting from the estimate of materials required, through specific stages of the purchase orders, managing the receiving goods and completing by linking to other modules like manufacturing work order and customer order. Also, you can organize your purchase invoices and supplier payments that are vital for your financials with Prodrun.