PRODUCT MANAGEMENT

If you are a manufacturer, then you should be familiar with the processes about

- Products

- Customers

- Suppliers

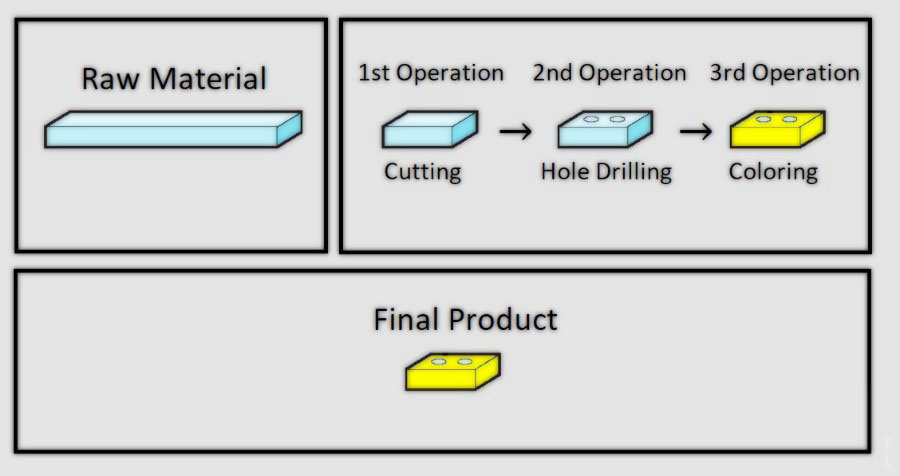

This three resources are the main source of your manufacturing process. To start with product; when you have a product to produce, then you should have value added operations. Prodrun lets you to track all your products and its value added operations in real-time from raw material to the final product.

You can organize bill of materials, your detailed product information, operation set-up and process time and semi-finished product.

Items on your production plant can be any form like,

- Raw Material

- Work-in-Progress Inventory

- Semi-finished Goods

- Maintenance, Repair and Operating Supplies

- Final products

With Prodrun, you can track and analyse all of them within seconds.

CUSTOMER MANAGEMENT

Tracking customer orders with manufacturing based ERP software can help improve your customer service efforts. Prodrun lets you to track all your customer orders in a smart way. Also you can organize customer invoices with its receipts and cash flow. In a traceability system, customer order is a top priority step.

Customer order is at the beginning of the traceability system. Capturing the order, shipping the product and integrating it with the manufacturing work order is very required process for a manufacturing company. With Prodrun, you can see the history of every tracing step with a perfect relation and integration.

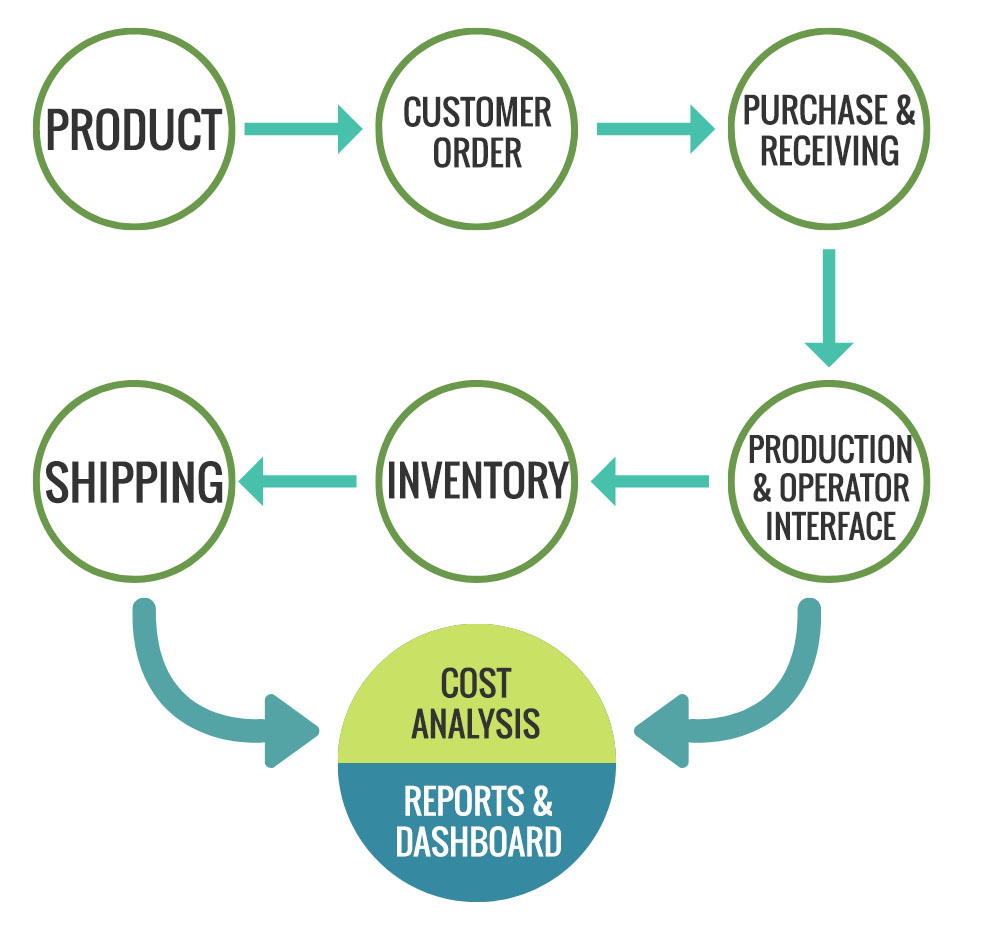

This is an example step list of a traceability system,

- Taking customer order

- Planning material requirements

- Placing purchase order

- Receiving material

- Opening manufacturing work order

- Shipping to customer

As you can see, it starts with the customer and ends with the customer again. All phases are customer-related steps and must be integrated each other.

PURCHASE MANAGEMENT

Purchase item that required for the production should be any of these:

- Raw material

- Tooling

- Manufacturing support item

- Mold

- Supplies

- Packaging material

- Services (required for specific work order)

- Other

All of them are related to your specific value added operations. To integrate a purchase order into a traceability system, you should define your purchase items and suppliers.

There are some important data that need to be tracked in raw material receiving process.

- Order date

- Delivery date

- Status

- Quantity

- Price

- Currency type

- Related work order

- Related customer order

Prodrun’s Purchase Management module traces the purchasing process starting from the estimate of materials required, through specific stages of the purchase orders, managing the receiving goods and completing by linking to other modules like manufacturing work order and customer order. Also, you can organize your purchase invoices and supplier payments that are vital for your financials with Prodrun.

PRODUCTION MANAGEMENT

When your customer and purchase orders are completed, you have to open a work order for product or parts to be produced. The quantity and deadline belongs to your customer order or your inside inventory requirements. The manufacturing work order comes with the product’s predefined operations.

You can also set the production planning for any workstation after you open the work order. For outgoing operations, you can add outsource work orders from Outsource Manufacturing.

There are 5 statuses for ongoing operations. These are;

1. In Queue

2. On Set-Up

3. In Process

4. On Downtime

5. Completed

Wherever you are, you can see the current status of your operations and workstations on your laptop, tablet, desktop or mobile phone.

OPERATOR INTERFACE

The operator can see everything about operation and work order from their tablet/interface and you can see the current status of the workstation, operator or work order wherever you are. For example, when operator touches the downtime button, you can see the status of the workstation as on downtime. The operator can also detail the downtime with the information of its type, time, description on related product or workstation.

It is very simple to use. On the dashboard, you can see every workstation with the information of its own work order, operator, customer, operation no and the operator names. Operators can use the application from the tablet, laptop or phone.

Think everything you can do with papers on the area of manufacturing. For example writing notes, stating times and quantities, seeing technical drawings, checking downtime, reading operation instructions and other similar things that you can perform with papers. With Prodrun, you can perform all this actions and more on a very simple application. We believe our operator interface is simpler than any other manufacturing based operator interface. Just try it out for free and see it yourself!

INVENTORY MANAGEMENT

Prodrun’s inventory management system is very easy for tracking inventory levels like purchase items, semi-finished goods and final products. You can also define required items for every semi-finished goods/operations on bill of materials and the inventory system performs all inventory movements in background automatically. Receiving raw material, producing the part and shipping the product will affect your inventory counting instant and automatically.

No More Manual Action

If you perform the whole process as it should be, you don’t have to specify any inventory movements manually. Prodrun performs all in and out movements in background automatically. Whenever you want, the history of inventory movements is ready to be seen. Also you can define minimum inventory levels for your inventory alerts. It is easy as touching a button!

SHIPPING MANAGEMENT

If you want to see shipping performance of your business, then you should track shipping records after the production ends. Every shipping record should belong to a product or part of a customer, quantity and its specific dates. Also it must be related to a manufacturing work order for the traceability. The quantity that ships to customer triggers your product’s inventory status. System controls your customer’s due date and deadline to improve your shipping performance. You can analyse all your customer shipments in real-time.

Shipping is the final step of the traceability principle of Prodrun. If a customer wants to ask anything about the shipped product, you will be ready to answer every question about it from the receiving raw material to the shipping process. The power of reliability depends exactly on the power of traceability. And this is what your customer wants!

COST ANALYSIS

Every step you take in the factory costs something and you have to see if it’s a loss or not. Total amount of your expenses and total time of your manufacturing simply gives the information about your production costs. You can easily calculate hourly cost of your factory with the data collected from manufacturing work orders.

You can also see the profit and loss for every single product. If you want to reduce the operational costs, then you should know how much money and time you spend. With Prodrun, we want you to see your loss in a very simple and fast way. To earn more, it is more important to know first how much you lose.

REPORTS & DASHBOARD

After you collect your data from processes, in the end, you will be ready to see reports that are very important for your business data analysis. For example; completed operations, customer and supplier total balance, downtime records, operations in queue, shipping performance, total working times of workstations, unreceived purchase order items, unshipped customer order items, workstation and operator performances, etc.

Some simple reports or instant information can be seen on the dashboard like total working hours, operation notifications, currently active workstations, etc.

In Prodrun, there is no limit for expanding your reports and dashboard. You can export all your reports into PDF or Excel file. Also, you can request for your own custom reports and we would love to make it happen for your business growth!

Prodrun’s business processes designed with the traceability principle can be seen in the graph below.